Nov 14,2024

0

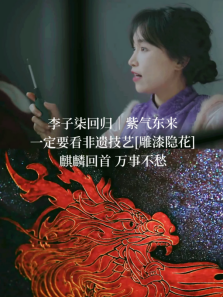

On the afternoon of November 12, Li Ziqi, the internet celebrity with over 100 million followers, posted a video on her social media platform showing the making of a lacquer art piece. The word "lacquer" is a homophone for "Qi" , and she named this carved lacquer piece “Purple Qi Coming from the East.”

The lacquerware, “Purple Qi Coming from the East,” presents subtlety, depth, inclusiveness, delicacy, warmth, and change, exuding an incomparable beauty and individuality that deeply resonates with every viewer.

Besides admiration, you may be curious why such exquisite lacquer art has not been promoted in the market?

01."Purple Qi Coming from the East" Panel: A Masterpiece of Craftsmanship, Hard Earned

In the 14-minute video, Li Ziqi deeply recreates the process of lacquerware making, showcasing high-level techniques such as the creation of the lacquer base, carving, and decoration. It is known that Li Ziqi trained under Yin Liping, a national-level representative inheritor of the craft, and during her training, she suffered from skin allergies due to the toxic urushiol in the lacquer.

In fact, creating furniture panels with lacquer is no easy task, and it’s also very difficult to use it on a large scale in the market. First, high-quality solid wood must be used for the wood base, which then undergoes 18 processes to create the lacquer base. Afterward, it goes through another 30 processes, including polishing and burnishing, to complete a panel suitable for decoration. Next, techniques such as grinding, painting, and lacquer layering are applied for decorative painting. This step combines craftsmanship with creativity, requiring a long time to complete and testing both skill and patience to the fullest.

A lacquer panel can be said to be half natural and half human. Only an experienced lacquer artist can paint a beautiful panel "just right".

02.BANFERT Introduces a New Panel Coating Solution

The 8,000-year-old Chinese panel coating craftsmanship needs both inheritance and innovation. In the video, Li Ziqi spends months creating the "Purple Qi Coming from the East" panel, reflecting her affection for traditional Chinese culture. Banfert modern coating technology shines in the panel coating field through innovation, bringing new brilliance to the craft.

With over a decade of experience in the UV/water-based paint field, BANFERT combines its strengths in UV/water-based paints, adhesives, films, and craftsmanship. Its latest "Panel Coating Innovation Solution" focuses on efficient processes and environmental friendliness in panel coating, aiming to create panels that are not only more beautiful but also more functional.

03.Efficient Positioning: Creating a More Beautiful and Functional Panel

In the face of the vast panel market, diversified, innovative, market-oriented, branded, and international coating solutions are both a trend and an opportunity.

BANFERT innovative solutions for sheet metal coating are committed to providing customers with high-quality coating materials and technical support. The specific contents of the solutions are as follows:

Innovative solutions for board finishing

Application process of wood board:

Substrate + (PUV penetrating glue) + PUR glue flat pasting decorative film

Application process of inorganic board:

Substrate penetration treatment + PUR flat pasting/coating decorative film

Application process of composite board:

①Two-component PU structural glue, bonding composite substrate;

②PUR glue flat pasting/coating lightweight composite board (decorative film + PUR glue)

Advantages: PUV penetrating glue replaces triamine paper process, lower cost and fast production turnover

Applicable Substrates

Provided Products

Application Scenarios

How to Improve Coating Efficiency?

Technology Integration: By combining UV coating technology with BANFERT independently developed products such as PUR adhesives, penetration adhesives, and films, the process is optimized to reduce costs.

Equipment Innovation: Innovating equipment based on the process to optimize production lines and enhance production efficiency.

Environmental Protection and Energy-saving Technology: By using low volatile organic compound (VOC) coatings and energy-efficient equipment, both environmental protection and energy consumption are reduced, further enhancing production efficiency.

Quick Response Mechanism: BANFERT has established a quick response mechanism to promptly address issues that arise during production, reducing downtime and rework rates, ensuring continuous and efficient production.

How to Make Panels More Beautiful?

BANFERT has a professional CMFP design and creative team, led by PhD and Master’s degree holders, specializing in color trends, color design, texture development, and more. Through CMFP design, the company comprehensively enhances product strength and provides personalized services.

The appearance design of the board surface finishing solution is implemented as follows:

Paint color: Develop and apply paint colors based on market demand and consumer aesthetics, and provide customers with a one-stop multi-color application solution.

Film Materials: BANFERT independently develops high-performance film materials that can be customized and personalized based on market and customer needs. These materials support the development of various colors and textures, achieving effects such as wood grain, stone patterns, and metallic textures.

Conclusion:

BANFERT not only strives for excellence in product quality but also continuously innovates in coating technologies, providing customers with efficient, reliable, and diverse panel finishing solutions. Just as Li Ziqi will continue to inherit and promote traditional culture, BANFERT will also keep exploring and innovating in the coating field, contributing to the development of panel finishing.