Dec 20,2024

0

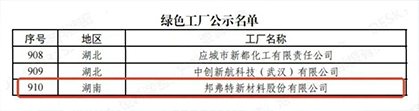

Recently, the Department of Energy Conservation and Comprehensive Utilization of the Ministry of Industry and Information Technology announced the list of green manufacturing for 2024, and BANFERT New Materials Co., Ltd. was awarded the national 'Green Factory' honor.

Under the global context of climate change and the dual-carbon strategy, green development is an inherent requirement for enhancing the resilience and security of the industrial chain, as well as the foundation for high-quality development.

BANFERT, as a leading enterprise in the green development of the chemical new materials sector, began with environmentally friendly chemical materials such as floor UV coatings. The company focuses on green, high-end, and refined development, and currently integrates the research, production, sales, and service of eco-friendly chemical new materials such as environmental coatings, adhesives, and decorative films. Moreover, BANFERT promotes green concepts across all aspects of its operations, implementing green management throughout the entire product lifecycle—from design and development, raw material selection, and production to recycling and reuse. This drives its green and low-carbon transformation while fulfilling environmental responsibilities and corporate social responsibilities.

The application and certification for the national-level "Green Factory" follow strict standards and regulations. These require factories to meet conditions for green development, including land use intensification, harmless raw materials, clean production processes, waste resource utilization, and low-carbon energy consumption. Additionally, it is specified that green factories must, while ensuring product functionality, quality, and the occupational health and safety of workers during production, adopt a lifecycle approach. They should prioritize the use of green raw materials, processes, technologies, and equipment, and meet requirements in terms of infrastructure, management systems, energy and resource input, with a focus on continuous improvement.

BANFERT has strategically advanced its "green and environmental protection" initiatives by integrating green development into the entire process of business management. The company has continuously strengthened the research, development, and production of low-pollution coatings, aligning its operations with sustainable practices. In recognition of its efforts, BANFERT was awarded the title of "National Industrial Product Green Design Demonstration Enterprise" in 2023. This honor highlights the company's commitment to green innovation and its active role in promoting environmentally friendly practices within the chemical materials sector.

Driven by the "environmental protection" trend and changes in the market structure, the company used its existing production plant and equipment to transform a 5,000-ton oil-based paint production line into a 5,000-ton water-based paint production line. At the same time, it also co-founded the "Green High-Performance Paint Research Center" with Hunan University to maximize the integration of both parties' advantages in the research and development of green products.

Through continuous technological and material innovation, BANFERT has developed a series of new chemical materials that are more environmentally friendly, efficient and low-carbon. For example, the "Key Technology for Synthesis of Green High-Performance Water-Based Resins and Coating Applications" won the "Second Prize for Technological Invention in Hunan Province".

In terms of automation technology, BANFERT develops enterprise automation technology, improves processing technology, and increases production efficiency.

Applying the green coating intelligent manufacturing control system based on the industrial cloud platform, the company combines advanced intelligent manufacturing equipment with the manufacturing execution system MES as the core, and efficiently collaborates and integrates with ERP systems, PLM systems, WMS systems, etc., to carry out carbon footprint, water footprint and environmental impact analysis and evaluation of product life cycle, strictly control infrastructure, management system, energy input, environmental emissions and other indicators, build a coating intelligent factory with intensive land use, clean production, waste resource utilization, and low-carbon energy, build an important domestic high-end environmentally friendly coating production base, expand production scale, and greatly improve the level of intelligent and clean production.

In terms of energy conservation and emission reduction, BANFERT has built a complete sewage treatment system to treat wastewater in a graded manner, and domestic sewage and cleaning wastewater continue to use the existing sewage treatment system.

At the same time, the company carried out energy-saving transformation by optimizing energy consumption structure, updating equipment and strengthening management, such as changing natural gas boiler heating to centralized steam heating and establishing distributed photovoltaic power stations.

At the same time, the company carried out energy-saving transformation by optimizing energy consumption structure, updating equipment and strengthening management, such as changing natural gas boiler heating to centralized steam heating and establishing distributed photovoltaic power stations.

In the future, BANFERT will continue to be guided by Xi Jinping's thoughts on ecological civilization, focus on the company's development concept of "new materials empowering a better life", fully implement the green factory management policy, gather "green synergy" with greater efforts, use green and low-carbon to drive industrial transformation and upgrading, and lead the environmental protection chemical new materials industry towards a green and sustainable new future.